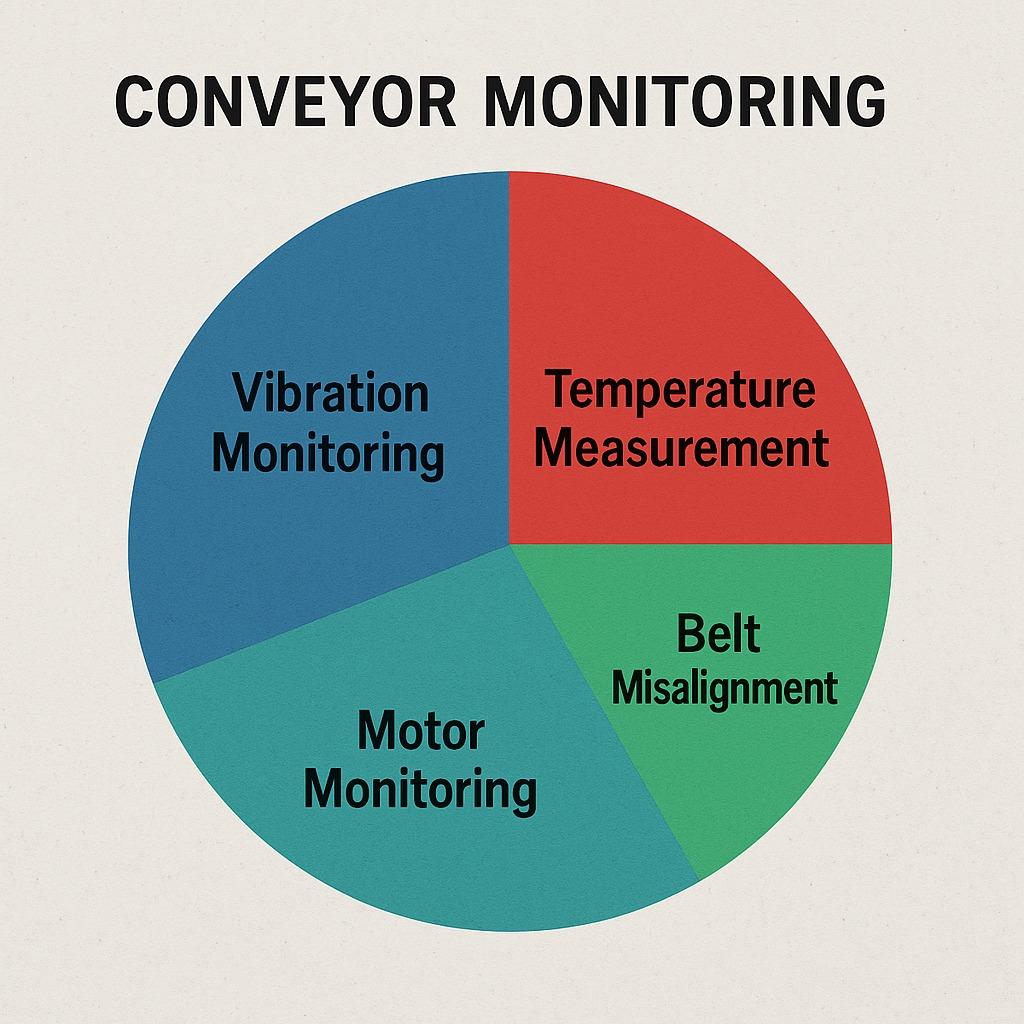

Innovations and Strategic Developments in the Conveyor Monitoring Market

The Conveyor Monitoring Market is experiencing significant growth, driven by technological advancements, strategic mergers and acquisitions, and substantial investments by leading companies. This press release highlights the top five companies with the largest market share, recent mergers and acquisitions, developments in the market, and new funding or investments within these organizations.

Top Five Companies with the Largest Market Share

-

ContiTech AG: As a division of Continental AG, ContiTech specializes in rubber and plastics technology, offering advanced conveyor belt monitoring solutions that enhance operational efficiency and safety across various industries.

-

Emerson Electric Co.: Emerson provides innovative automation solutions, including sophisticated conveyor monitoring systems that utilize sensors and IoT technologies to optimize performance and prevent failures.

-

Honeywell International Inc.: Honeywell delivers a broad range of industrial solutions, with conveyor monitoring systems designed to improve safety and efficiency in material handling operations.

-

Fenner Dunlop: Specializing in conveyor belt technologies, Fenner Dunlop offers comprehensive monitoring solutions that focus on predictive maintenance and reducing operational downtime.

-

Yellow Technical Services (Pty) Ltd.: Based in Australia, Yellowtec provides specialized conveyor monitoring solutions tailored to the mining and industrial sectors, emphasizing reliability and performance.

Request Sample Link : https://www.maximizemarketresearch.com/request-sample/261837/

Latest Mergers and Acquisitions

-

Mining3 and Ava Group: In February 2019, Mining3 and Ava Group launched an innovative predictive asset monitoring solution for conveyors, incorporating advanced fiber optic sensing technology.

-

Semtech Corp and Transco Industries: In February 2019, Semtech Corp and Transco Industries formed a partnership to deliver a remote monitoring solution for conveyor belts.

Recent Developments in the Market

-

4B Components: In May 2019, 4B Components inaugurated a new advanced elevator bucket injection molding facility in Morton, Illinois. This 45,000 square feet facility enhances manufacturing efficiency, boosts production capacity, and improves responsiveness to the needs of the agricultural and industrial sectors.

New Funding or Investments

As of now, there are no publicly disclosed new funding rounds or significant investments in the listed companies. However, these organizations continue to allocate substantial resources towards research and development to drive innovation and maintain their competitive edge in the conveyor monitoring market.

Conclusion

The conveyor monitoring market is witnessing dynamic growth, propelled by the strategic initiatives of leading companies. Through mergers and acquisitions, product innovations, and a steadfast commitment to research and development, these organizations are enhancing their market positions and contributing to the advancement of conveyor monitoring technologies. As the industry evolves, continuous investments in innovation and strategic collaborations will be pivotal in shaping the future landscape of the conveyor monitoring market.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Spellen

- Gardening

- Health

- Home

- Literature

- Music

- Networking

- Other

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness