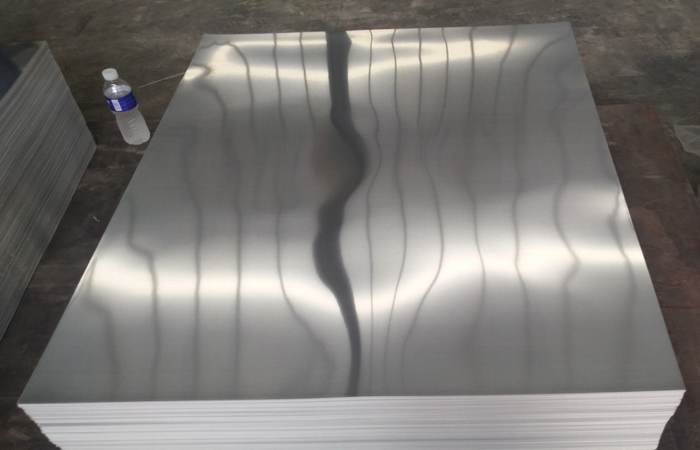

Grade of aluminum plate

According to the different metal elements contained, 4 x 8 aluminum sheet are widely used in electronics, packaging, construction, machinery and other fields. The grades of aluminum plates are mainly divided into pure aluminum plates (the composition is basically rolled from pure aluminum), alloy aluminum plates (composed of aluminum and auxiliary alloys, usually aluminum-copper, aluminum-manganese, aluminum-silicon, aluminum-magnesium and other series) . Aluminum and aluminum alloys are divided into nine categories. Among them, aluminum and aluminum alloys of 1000, 3000, 5000, 6000, and 7000 series are the main ones, and other series are less likely to be used in practice.

The grade of aluminum plate is divided into:

Category 1: 1000 Series: Industrial Pure Aluminum

The second category: 2000 series: aluminum copper alloy

The third category: 3000 series: aluminum manganese alloy

The fourth category: 4000 series: aluminum silicon alloy

The fifth category: 5000 series: aluminum magnesium alloy

The sixth category: 6000 series: aluminum magnesium silicon alloy

Class 7: 7000 Series: Aluminum-zinc-magnesium-copper alloys

The eighth class: 8000 series: other alloys

Class 9: 9000 Series: Spare Alloys

1000 series aluminum plate: 1050, 1060, 1070, 1100 and other grades, good formability and surface treatment, and its corrosion resistance is the best in aluminum alloys. Because it is pure aluminum, the strength is lower, and the higher the purity, the lower the strength.

2000 series - AL x Cu series aluminum plates, 2014, 2024 have high heat resistance, high strength, but poor corrosion resistance, good low temperature and high temperature characteristics, and excellent welding performance.

3000 Series - Aluminum x Manganese Series Aluminum Sheet, 3003, 3004, 3014, 3105, good formability, weldability and corrosion resistance. It is easy to process and has good rust resistance. Good heat dissipation performance and welding performance.

5000 Series - Aluminum x Magnesium Series Aluminum Sheets, 5052 Aluminum Sheet, 5083, 5086, 5454, 5754. Good workability, weldability, corrosion resistance, good finish after anodization, good formability, especially high fatigue strength, good seawater resistance.

The most widely used 6000 series aluminum sheets are 6061 and 6063 alloys. The alloy has the advantages of medium strength, high corrosion resistance, no tendency to stress corrosion cracking, good welding performance, constant corrosion performance in the weld zone, good formability and process performance.

- Art

- Causes

- Crafts

- Dance

- Drinks

- Film

- Fitness

- Food

- Jeux

- Gardening

- Health

- Domicile

- Literature

- Music

- Networking

- Autre

- Party

- Religion

- Shopping

- Sports

- Theater

- Wellness